Automatic temperature recording devices offer several benefits to transport refrigeration companies; not only do they ensure that things are faster, easier and more convenient for staff, but they also help businesses save money and minimise waste.

At CoolKit, we work proudly with Seven Telematics, who manufacture several high-tech variants of this advanced technology.

This week on the Coolkit blog, we’re going to take a quick look at the many advantages that these devices offer.

Solve problems quickly with a temperature recording system

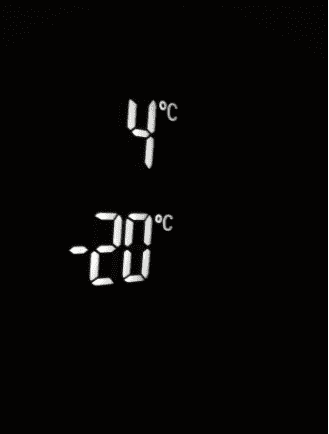

Temperature recording devices have many variations in their design depending on their specific use, but one of the functions they all have in common is that they’re programmed to send out warnings and alerts when temperatures are outside of their safe parameters. This allows staff to react to problems far more promptly than they otherwise might be able, making the potential consequences much less severe.

While this is useful with a variety of products in transport refrigeration, it’s especially advantageous when dealing with extremely climate-sensitive products such as pharmaceuticals and medical supplies. The longer such products remain at incorrect temperatures, the more devastating it is to their integrity, making prompt responses key to their continued survival. Some temperature recording devices also keep detailed historical logs, which can be immensely useful in identifying recurring problems. Staff can narrow down any breaks in the cold chain by looking through these records, which can help them stop these issues from developing in the first place.

Efficient temperature data logging

Manual logging is a viable method of collecting data, but it does open firms up to the risk of human error. Typos or pencil smudges can result in key information being obscured or incorrectly logged. However, the automated reports offered by temperature recording devices solve many of these problems from the outset. The data is collected and logged instantly, which means that it’s both more accurate than manual logging, and saves the time and manpower required to do so.

Reducing product waste with accurate temperature solutions

Climate-sensitive products by their very nature often have little margin for error, and mistakes can be costly. If products are exposed to incorrect temperatures for long periods of time, it’s common for entire batches to be disposed of. Ongoing issues – even minor ones – can thus have huge impacts on businesses. Meanwhile, other issues aren’t discovered until products are on shelves, necessitating product recalls. This has not only financial repercussions but can also have drastically negative effects on the public’s perception of a business.

With temperature recorders, companies can predict, identify and resolve developing problems before they evolve into serious issues, allowing them to make significant savings both in terms of finance and stock.

Want to find out more? Read our blog on Seven Telematics and their vehicle temperature monitoring solutions.